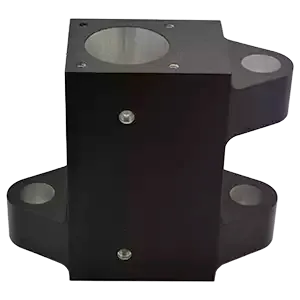

CNC Machined Parts

Multi-axis milling & turning for tight-tolerance components—prototype through production.

Build-to-print parts and assemblies delivered right the first time under AS9100D / ISO 9001, ITAR registration, and CMMC Level 2 controls. Machining, sheet metal, and finishing coordinated end-to-end.

Multi-axis milling & turning for tight-tolerance components—prototype through production.

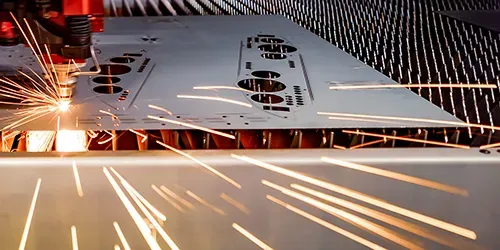

Laser/waterjet cutting, forming, hardware insertion, and welded/riveted assemblies.

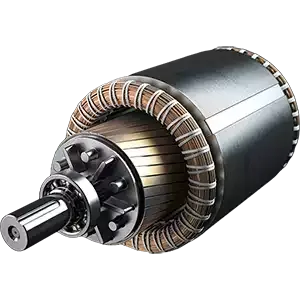

Turnkey mechanical subassemblies with documentation and traceability.

Fast iteration for fixtures, prototypes, and low-volume end-use parts.

Anodize, chem film, plating, passivation, primers/paint, heat treat coordinated through trusted partners.

AS9100D / ISO 9001:2015 Certified Quality Management System with first-article reporting, documented inspection, and full traceability.

Production under AS9100D / ISO 9001:2015 with ITAR registration and CMMC Level 2 controls, calibrated inspection, and controlled suppliers.

Clear DFM guidance up front; stable setups & fixturing for repeatability.

Finishing and documentation handled end-to-end so parts arrive truly “ready.”

Proactive communication and schedule visibility throughout the build.

Continuous improvement and feedback to reduce cost and risk over time.

Confirm materials, finishes, tolerances, inspection level, and documentation.

Optimized production program for your requirements.

In-process checks and final verification; certs and reports packaged to your PO.

Protective packaging, labeling, and on-time delivery.

Equipment investments, certifications, and process improvements from the Harley & Son team.